Written by Franca Trippler

In the post-Covid world, optimizing flows is a ‘must-do’ task for material handlers. For any business looking to modernize its warehouse or worksite, autonomous solutions need to be at the top of the list.

Supply chains are under pressure

Over more than three decades, companies from heavy industry, to light retail have honed their ‘just-in-time’ processes to perfection.

But times have changed. A global pandemic and changing market dynamics mean material handlers now face a logistical headache and rising costs. As they balance compliance with new restrictions and keeping pace with demand, the industry is entering a new era – of digital supply chains incorporating greater levels of automation, intelligent systems, and autonomous transport solutions.

Towards the next normal

Even before the pandemic, global supply chains were showing signs of wear and tear. Businesses questioned their over-reliance on one region, supplier – or even a single factory.

Covid has exposed the current system’s frailty. Transport restrictions led to bottlenecks; slowing or even stopping production. Operations have been rapidly remodeled, including limiting employee numbers onsite. Companies have invested vast amounts of cash in protective equipment and safety measures.

At the same time, the pandemic has dramatically reshaped expectations in some sectors. In e-commerce, for example, the market is booming. Latin America (previously slow to take up online shopping) saw millions of new customers order over the internet for the first time in 2020. Not only that, but more e-shoppers want their goods to arrive faster. Next-day (or even same-day) delivery isn’t a luxury for experienced e-shoppers, they deem it a necessity.

All industries are approaching an age of new market dynamics. These are foremost in operators minds as they upgrade to greater levels of automation and data exchange.

The future of digitization is greater autonomy

Modern warehouses and material handling services are already on their way towards Industry 4.0. Businesses have embraced advanced robotics and automated guided vehicles (AGVs) to streamline their material handling processes.

But meeting the new demands means they must go further. Equipment, transportation, and site architecture need to work seamlessly with intelligent warehouse management systems to give material handlers greater levels of agility.

Most AGV while well established as a safe and efficient way of moving goods and materials, are limited to indoors and unsuited to more dynamic environments. Operators need to step up a level and explore the benefits which come with greater levels of autonomy.

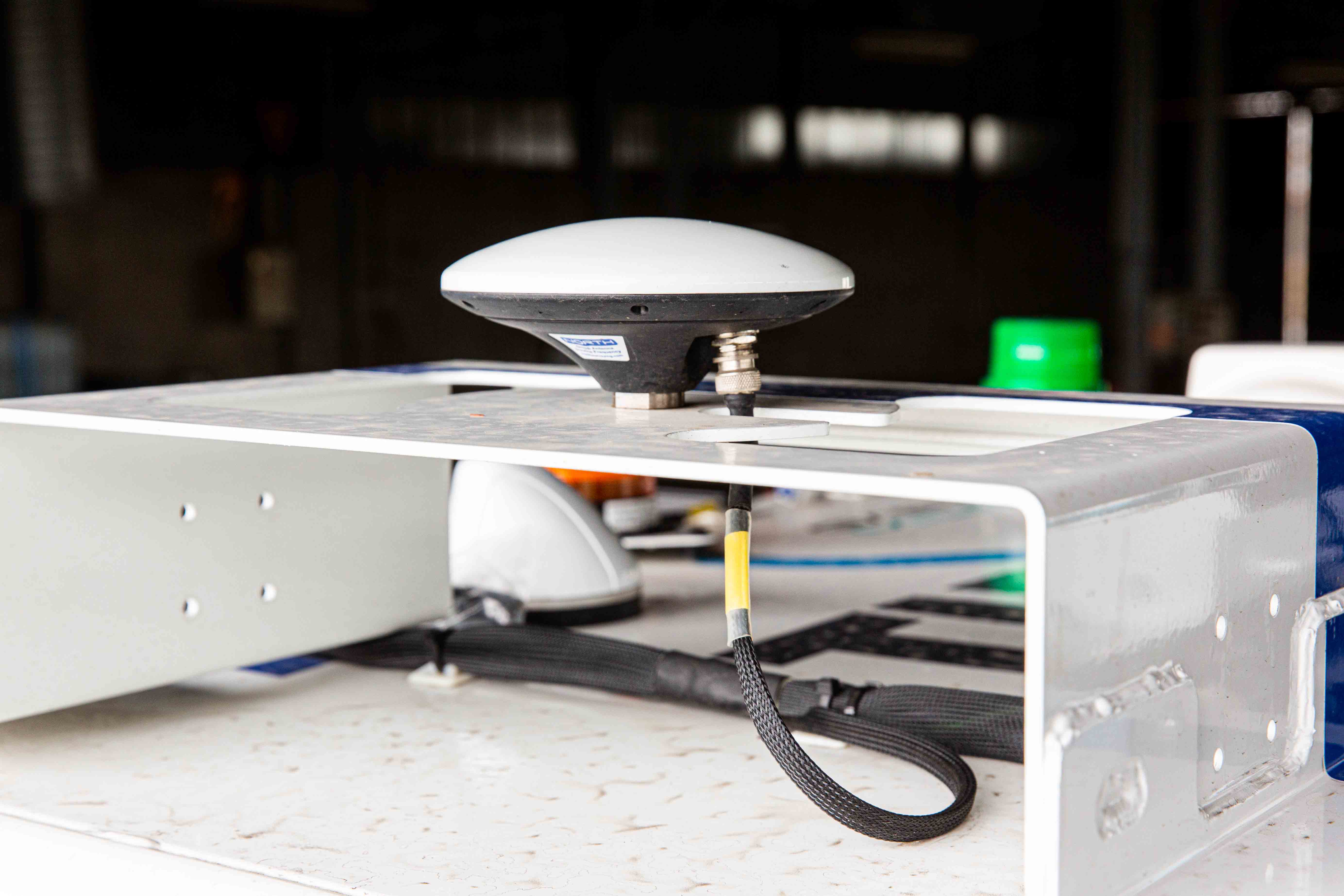

As an example, Stellantis (Peugeot-Fiat-Chrysler), Europe’s second-largest car manufacturer is increasing the levels of autonomy to streamline production flows at its Sochaux manufacturing plant. With the facility producing more than 2,000 vehicles per day, it has introduced several autonomous tow tractors to serve its assembly lines for the Peugeot 3008 and 308.

Working in shifts, the driverless vehicles connect the indoor and outdoor elements of the plant, making 3km round trips between the supplier park and assembly shop, delivering parts such as bumpers, tailgates, and consoles.

The autonomous vehicles help optimize Stellantis’ production lines and have increased safety and flexibility, while significantly reducing operating costs.

Pressing the reset button

As we look forward, past the pandemic, there’s an opportunity for material handlers to press reset and reconsider how their business operations should look in the future. Digitalization using autonomous solutions brings three key benefits:

Flexibility

Increased intelligent systems allow businesses to offer a more individualized service. As next day and same day become the norm, digitalization allows operators to be faster and more flexible to keep up with increasing demand.

Cost-effectiveness

Operators are now diversifying suppliers and decentralizing inventories to remain resilient to crisis. This takes investment, with smaller, more widespread distribution centers and regional warehouses, as well as the potential for higher labor costs.

This is especially important in those sectors hardest hit by Covid. Carmakers for example are paying even closer attention to margins as demand has dropped. Digitalization gives them greater control over their costs.

Safety

More than anything else, autonomous solutions and increased digitization will lead to safer operations. This means preventing accidents and cutting risk to both staff and processes. Covid has brought an extra strand to this safety in the workplace, as companies look to pandemic-proof their businesses, ensuring employees can stay at minimum distances, if they are required to by future regulations.

Supply chains are changing at a rapid pace. Planning in these solutions from the ground up is essential.

Investing early in autonomous solutions will help create businesses that are more resilient to future uncertainty.

Franca is part of EasyMile's communications team and is passionate about autonomous technology and its impact on the future of mobility and logistics.