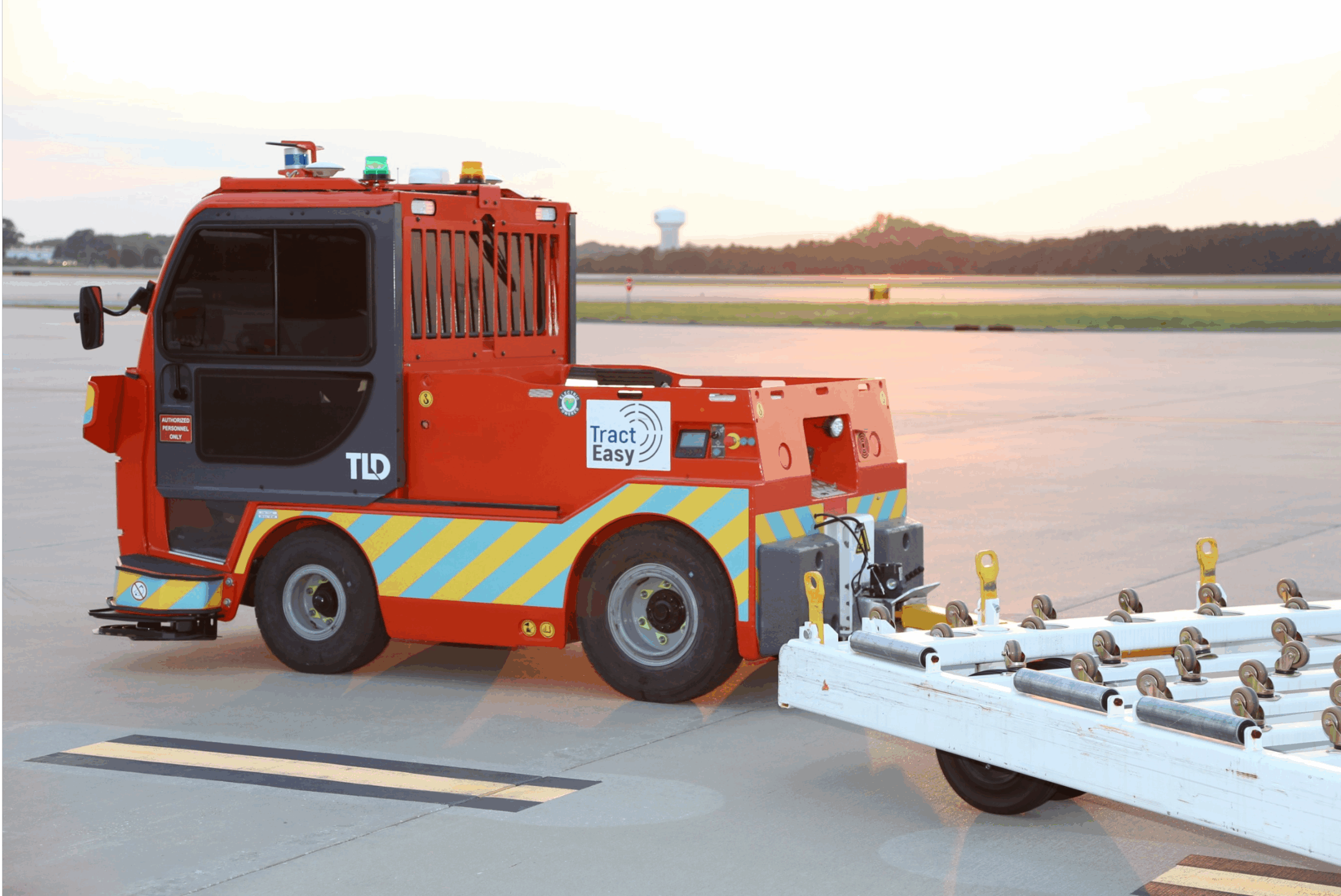

New feature: Automated hooking and unhooking

Why does this matter? Because in logistics yards and airport ramps, every minute counts. Manual trailer handling eats up time, requires trained personnel, and introduces safety risks. With this new feature, EZTow completes missions end-to-end, reliably and repeatedly, even when no one’s around.

It’s one more step toward smoother operations, fewer delays, and a future of truly autonomous logistics.

Link to the video here: https://youtu.be/40gljge4A1Q

Time savings that compound over time

In traditional operations, hooking and unhooking trailers manually can be a slow and sometimes unpredictable task, especially during shift changes or at night when staffing is limited. Automating this process allows EZTow to move seamlessly from one task to the next, cutting down on idle time and keeping mission schedules tight.

In high-throughput environments like airports and industrial production sites, these saved minutes add up, streamlining turnaround and boosting overall site productivity.

Autonomous operations, day and night

EZTow is already designed to operate autonomously across complex routes, and with this new feature, it can now complete full missions end-to-end without human intervention. That includes reversing, aligning with trailers, hooking up, and moving on, no manual override required.

Whether it’s a late-night cargo transfer at an airport or a 5 a.m. industrial shift change, the system works around the clock, maintaining consistent service levels even in low-light or low-staff conditions.

Better use of labor and safer working conditions

The logistics and aviation sectors face persistent labor challenges, especially for physically demanding roles like trailer handling. EZTow’s automated coupling system reduces the need for staff to manually align, hook, or disconnect trailers, tasks that typically involve bending, lifting, and operating in tight spaces between vehicles.

By removing this step from human responsibility, operations can:

- Free up staff for more strategic or supervisory roles.

- Minimize the risk of injuries, particularly musculoskeletal and pinch-point accidents.

- This makes it a safety win as much as an efficiency gain.

Reliable, precise, and repeatable

Where human intervention might vary from one operator to the next, EZTow’s automated hooking process is always precise. The system aligns with the trailer, backs up, and connects accurately every time. This improves uptime and reduces wear and tear on both the vehicle and trailer systems.

For logistics operators, this means:

- Fewer service interruptions due to misalignments or failed hookups.

- A standardized, repeatable process that’s easy to scale across fleets.

Seamless integration into existing missions

The automated hook/unhook feature is not a standalone add-on. It’s designed to feel like a natural extension of EZTow’s mission logic. No special markers, modifications, or infrastructure changes are needed, just smarter autonomy that supports your existing workflows.

This ensures smoother rollouts, quicker adoption, and faster ROI.